Rilson manufactures Nonmetallic gaskets that meet ASME, JIS, BS, DIN & other international standards, offering a wide range of sealing solutions that are specifically designed to meet the needs of various industries. Our nonmetallic gaskets, made from materials such as

· Compressed Nonasbestos

· PTFE

· Graphite

· Rubber

· Cork

· Mica

provide chemical resistance, high-temperature capability, and

exceptional sealing performance for industrial applications.

- MT : +86-574-63119187

- Email: [email protected]

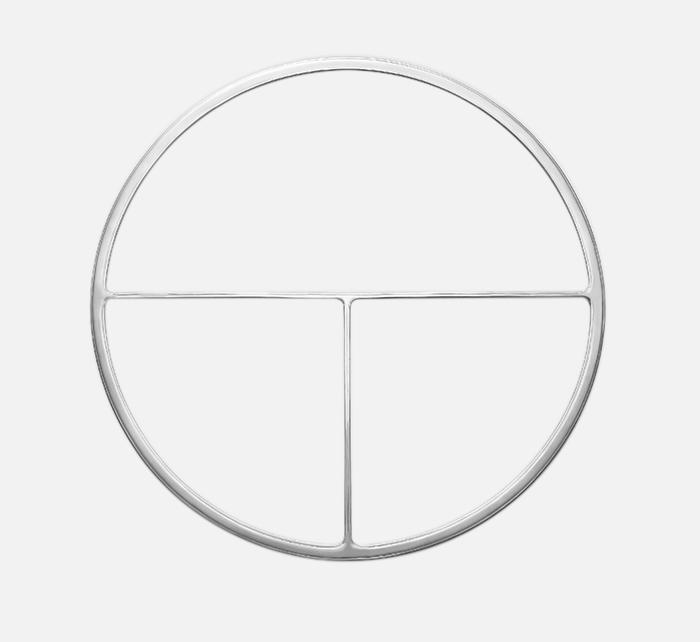

Non Metallic Gaskets

Product Details

Compressed Non-asbestos Gaskets

Compressed Non-asbestos Gaskets are sealing devices designed to create a tight, leak-proof connection between two flange surfaces in industrial applications. Compressed Non-asbestos Gaskets are a blend of fibers and rubber materials bound together. They are designed to create a tight seal between two flange surfaces in industrial applications.

A wide range of compressed sheet materials are available in a variety of fiber and rubber combinations that are chosen for their compatibility with specific chemicals and resistance to high temperatures. Sheet gaskets are designed with the compressibility necessary to fill in the voids of the flange surfaces and the resiliency to maintain the seal with temperature and pressure fluctuation.

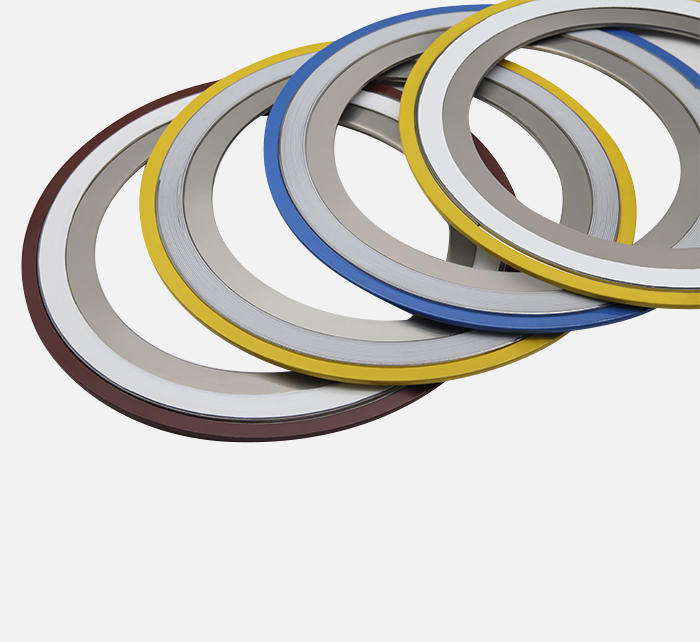

PTFE Gaskets

PTFE (Polytetrafluoroethylene) has emerged as the common thermoplastic gasket material. PTFE's outstanding properties include resistance to temperature extremes from cryogenic to 500°F (260°C). PTFE is highly resistant to chemicals, solvents, caustics, and acids except for free fluorine and alkali metals. It has a very low surface energy and does not adhere to the flanges. PTFE gaskets can be supplied in a variety of forms; either as virgin or reprocessed material, and also with a variety of filler material.

Graphite Gaskets

Graphite gaskets are used to seal joints in adverse conditions. There are several types of graphite gaskets including: flexible, reinforced, tape, spiral, foil, and ring gaskets. These types of graphite gaskets all have properties in common including chemical inertness, high strength, resistance to creep, and low coefficient of friction.

Applications for graphite gaskets include pipework, heat exchangers, automotive engines, and petrochemical processing plants.

By using a graphite gasket, the gap in a joint can be more effectively sealed, which can increase the performance of the system. Graphite gaskets are desirable over other gaskets due to their longevity.

Rubber Gaskets

Rubber gaskets play a crucial role in sealing the interfaces between parts. Their primary purpose is to prevent leakage, ensuring airtight or watertight seals between two surfaces. These flexible components are commonly made from elastomers like neoprene, EPDM, silicone, or nitrile. Each material offers unique properties.

Cork Gaskets

The distinctive qualities of cork gaskets, which are well known for their flexibility and durability, make them widely used in a variety of industries. Cork gaskets are highly compressible and work well to seal joints, stopping leaks in commercial, residential, and automobile environments. They are durable in harsh conditions because of their innate resistance to chemicals and oil.

Mica Gaskets

Mica gasket material is exceptional in its resistance to high heat. At temperatures over 900 F, the ideal sealing material flexible graphite cannot be used.

Flexible graphite will coke at those elevated temperatures when oxygen is present, whereas mica gasket material will not (900 - 1850 F). Mica gaskets can be

very effective in sealing those high-temperature critical applications without failing due to the presence of oxygen.

Our clientele hails from various parts of the globe, and through our extensive experience in the industry, we have earned the trust and recognition of our customers. Presently, we have obtained certifications from several prominent companies. Additionally, we have successfully achieved ISO9001:2015 quality management system certification, as well as the API 6A certificate, among others.

As a professional Non Metallic Gaskets factory, The company is dedicated to delivering value to customers, promoting health and happiness among workers, and producing positive social effects. We uphold the core principles of integrity, precision, innovation, and mutual success. With the aspiration of becoming the preferred brand in industrial gaskets, we are committed to establishing ourselves as a top-tier player in the fluid sealing industry and working towards the objective of ensuring mutual satisfaction among customers and employees.

-

The design of a Kammprofile gasket is specifically engineered to enhance its sealing performance, making it one of the most reliable gasket types used...

READ MORE -

Kammprofile gaskets are widely regarded as one of the most reliable sealing solutions for critical applications, particularly in industries where high...

READ MORE -

In the petrochemical industry, where safety, durability, and efficient operations are paramount, the choice of sealing materials plays a critical role...

READ MORE -

In industrial systems that operate under both high-pressure and high-temperature conditions, ensuring the integrity of seals is essential to maintaini...

READ MORE

In industrial production, non-metallic gaskets are key sealing components, and the stability and reliability of their performance are directly related to the safe operation of the entire system. Therefore, correct maintenance is essential for non-metallic gaskets. Ningbo Rilson Sealing Material Co., Ltd., not only provides high-quality non-metallic gasket products, but also knows the importance of maintenance and provides customers with comprehensive maintenance guidance and support.

1. Regular inspection and replacement

Non-metallic gaskets will be affected by various factors such as medium pressure, temperature, chemical corrosion, etc. during use, and their performance will gradually decline. Therefore, regularly checking the wear, deformation and sealing performance of the gasket is the primary task of maintenance. Once the gasket is found to be aging, damaged or the sealing performance is reduced, it should be replaced in time to avoid safety hazards such as leakage.

2. Keep the sealing surface clean and flat

The cleanliness and flatness of the sealing surface directly affect the sealing effect of the gasket. Therefore, during maintenance, impurities, dirt and rust on the sealing surface should be cleaned regularly to ensure that the sealing surface is clean, smooth and scratch-free. At the same time, the uneven sealing surface caused by flange deformation or loose bolts should be repaired and adjusted in time.

3. Reasonable installation and tightening

Correct installation and tightening are the basis for the normal operation of non-metallic gaskets. During the installation process, it should be ensured that the gasket is completely fitted with the flange sealing surface without offset or distortion. At the same time, when tightening the bolts, the principles of symmetry, cross, and gradual force should be followed to ensure that the gasket is evenly stressed and avoid leakage caused by local overtightening or over-loosening.

Ningbo Rilson Sealing Material Co., Ltd. has advanced production equipment and a technical team that can produce high-quality and high-performance non-metallic gasket products. The company pays attention to the selection and quality control of raw Material to ensure that each gasket meets international standards and customer requirements.

Ningbo Rilson not only provides high-quality products, but also focuses on providing customers with professional maintenance guidance. The company has an experienced technical team that can provide customers with comprehensive maintenance advice and solutions. Whether it is the preparation work before installation, precautions during installation, or later maintenance, the company can give customers professional guidance and support.

Ningbo Rilson Sealing Material Co., Ltd. adheres to the principle of "customer first, quality first" to provide customers with perfect after-sales service. The company has a special after-sales service department to handle customer inquiries, complaints and repair requests. Once customers encounter problems or need technical support during use, the company can respond quickly and provide solutions.

After an in-depth discussion of the maintenance requirements of non-metallic gaskets and the professional support of Ningbo Rilson Sealing Material Co., Ltd., it is not difficult to find that this is not just about the daily maintenance of a component or the service commitment of a company. In fact, they together constitute an important cornerstone for ensuring industrial production safety, improving equipment efficiency, and promoting sustainable development.

First of all, from the maintenance requirements of non-metallic gaskets, this is not only a technical job, but also an attitude of responsibility for production safety. Regular inspection and replacement, keeping the sealing surface clean and flat, reasonable installation and tightening, these seemingly simple maintenance steps are actually the key to preventing leakage and ensuring the stable operation of the system. Once these maintenance requirements are ignored, serious safety accidents and huge economic losses may occur. Therefore, strengthening the maintenance of non-metallic gaskets is of far-reaching significance for ensuring production safety and reducing accident risks.

Secondly, as a leader in the field of non-metallic gaskets, Ningbo Rilson Sealing Material Co., Ltd.'s professional support and service commitment is not only a commitment to customers, but also a contribution to the development of the industry. The company not only provides high-quality products, but also helps customers solve problems encountered during use through professional maintenance guidance and perfect after-sales service, and improves the overall performance and reliability of the equipment. This customer-centric and quality-oriented service concept has not only won the trust and praise of customers, but also promoted the progress and development of the entire industry.

Furthermore, the continuous contribution of Ningbo Rilson Sealing Material Co., Ltd. is not only reflected in the technology and product levels, but also in its promotion of industry standards and specifications. The company continues to lead the industry to a higher level through its own technological innovation and quality improvement. At the same time, the company also actively participates in industry exchanges and cooperation, discusses and solves the problems and challenges faced by the industry with peers, and contributes wisdom and strength to the healthy development of the industry.

English

English русский

русский 中文简体

中文简体 Reinforced Graphite Gasket with inner and outer eyelets

Reinforced Graphite Gasket with inner and outer eyelets Non Metallic Gaskets

Non Metallic Gaskets PTFE Envelope Gasket

PTFE Envelope Gasket PTFE Gasket

PTFE Gasket PTFE Joint Sealant

PTFE Joint Sealant Corrugated Graphite Tape

Corrugated Graphite Tape Graphite Tape

Graphite Tape